Extender For Plywood Adhesive

Polymate -111

The plywood Extender for synthetic Amino resin (EXTENDER-UF,MUF) to enhance bonding ,quality and reduce the glue cost.

Polymate -222

The plywood Extender for synthetic Phenolic resin (EXTENDER-PF)to enhance bonding ,quality and reduce the glue cost.

Polymate -333

The plywood Extender Cum Preservative for synthetic Amino resin (EXTENDER CUM PRESERVATIVE-UF,MUF)to enhance bonding ,quality and will protect the wood based panel products from termite,boarer and fungus.

Polymate -444

The plywood Extender for synthetic Phenolic resin (EXTENDER CUM PRESERVATIVE-PF) to enhance bonding ,quality and will protect the wood based panel products from termite,boarer and fungus.

Plywood Additives For Amino and Phenolic Resin

Polymate -888

The plywood adhesive industry is always searching for new technologies to achieve the best formulations for their customers. The ideal adhesive is the result of a smart combination of base polymers and additives, which allows the properties to be adjusted for a specific application.

The basic requirement to be innovative in this environment is a deep understanding of adhesive formulations, specifically how the effects and the interaction of different additives play a crucial role in the proper formulation of an adhesive.

Polymate -888 is a resin booster fpr amino (UF,MUF,MF) resin normally used in plywood industries ,designed to improve the rheological properties (Viscocity and bonding ) and to reduce the production cost.

Indian plywood Industries Research anf Training Institute (IPIRTI) taken our product as a project to study its efficacy and efficiency. IPIRTI certified the product with very good result. The report will be available if required.

Advantages :-

(i) It provides the solution for commercial and MR resin. Use 100% technical Urea and save upto 25% cost.

(ii)It makes very high resin viscosity and thickness(40-45 sec in B4)

(iii) Excellent additive for the pre-press bonding in amino resin using both the direct and indirect methods.

(iv)It reduces formaldehyde emissions and maintains a healthy working environment.

Product description

Identity : Resin booster (Additive for plywood adhesive)

1. Chemical product and company

IDENTIFICATION PRODUCT NAME:- (POLYMATE -888)

MANUFACTURER:- PATINA CHEMICALS

2. Composition/information on Ingrdients

CHEMICAL NAME: - Mixture of polyanionic cellulose ,vegetable tannin with some speciality chemicals as catalyst.

SYNONYMS:- Polymeric carbohydrate

3. Hazard Identification

May be harmful if inhaled, Non hazardeous in case of insgeastion.

Slightly hazardous in case of skin contact (irritant),May cause eye irritation.

4. First aid measures

GENERAL ADVICE: Wash off immediately with soap and plenty of water. In the case of respirable dust ,use self- contained breathing apparatus and dust impervious protective suit. Use personal protective equipment.

Inhalation: Move victim to fresh air. If breathing is difficult, give oxygen. If irritation persiSts, consult a physician.

Skin Contact: Remove contaminated clothes and shoes, rinse skin with plenty of water or shower. Use soap to help assure removal.

Eye Contact: Remove any contact lenses at once. Flush eyes well with flooding amounts of running water for at least 15 minutes. Assure adequate flushing by separating the eyelids with sterile fingers. If irritation perSists, consult a physician.

Ingestion: Rinse mouth, give plenty of water to dilute the substance. Never give anything by mouth to an unconscious person. Consult a phy

5. Handling and storage

Handling: Avoid contact with eyes, skin and clothing. Avoid prolonged or repeated exposure. Handle material with suitable protection.

6. Storage:- Store away from sunlight in well- ventilated dry place at room temperature. Keep container tightly closed. INCOMPATIBLE PRODUCTS: Acids, alkalis

8. Physical and chenical properties

APPEARANCE: - White free flowing powder

ODOR: - Characteristic. (Slight.)

SOLUBILITY : - Soluble in water

pH; :- 6 -7

FLAMMABILITY:- May be combustible at high temp.

9. Transport Information

Proper Shipping Name: None

Non‐hazardous for transport: this substance is considered to be non‐hazardous for transport.

10. Disposal Consideration

Dispose in a hazardous- waste site in accordance with all applicable regulations. Any disposal practice must be in compliance with country, local, state, and federal laws and regulations

11. Other information

No specific notes

The information above is believed to be accurate and represents the best information currently available to us. However, we make no warranty of merchantability or any other warranty, express or implied, with respect to such information, and we assume no liability resulting from its use. Users should make their own investigations to determine the suitability of the information for their particular purposes.

Polymate -666 (Mixed Tannin)

To increase the production efficiency and to manufacture the quality plywood, now a day’s pre-press technology before hot pressing become a common practice in modern plywood industries. Polymate-666(Mixed Tannin) is a special additive formulated with some white vegetable based tannin of Divi Divi estract with some speciality formulated complex catalyst etc.It doesn’t show any chemical reaction with Liquid resin even after mixing with hardener and buffer rather than forming creamy and is lump-free during mixing. Satisfactory rheological properties of the adhesive and physioco-mechanical properties of the plywood made with mixing resin technology was achieved.The primary purpose of Polymate-666 for the pre-press to allows the wet adhesive to “tack” to bring a temporary bonding in between glue core and panel core and easy to shifting is the basic function of pre-press technology for plywood manufacturing. Polymate-666 at 5% concentration on total liquid resin not only give high cold tackiness but also make reduction of pre press time up to 40 -50%.

It is an additive based on maximum percentage of tannin (white vegetable based tannin of Divi Divi estract,) natural gum , specialty tackfying chemicals and some complex catalyst available in local market as trade name Polymate-666 (Mixed Tannin)

Advantages:

(i) It is used in pre-press glue for both amino and phenolic system.

(ii) It makes glue, very high viscous and tackyness.

(iii) Reduces pre-press time and hot-press timing.

(iv) Ensure very good pre-press bonding.

(v) Production efficienccy increases by 20-25%.

Nature- White Vegetable based on modified Divi Divi Extract in powder form

Specification:- Appearance - White coloured very fine powder

Chemical Nature - Modified Pyrogallol tannin (Divi Divi)

Total Solids - 94 ± 1%

pH - 3.5 - 4.5

Ionic Character - Anionic

Dosage - 2 - 12% as per requirement

Shelf life - Unlimited if stored away from extreme conditions and humidity

Storage:- The product should be stored in a cool dry place and away from extreme conditions and humidity. Some caking may occur during prolonged storage, but this does not deter the quality of the product.

Product description

Identity:- Mixed Tannin (Special pre- press additive )

1.Chemical Product and company

Idenrisication product name:- POLYMATE -666

Mabufacturer:- PATINA CHEMICALS

2. Compositiin/infoemation on ingredients

CHEMICAL NAME: - Tannin (white vegetable based tannin of Divi Divi extract,) natural gum , specialty tackfying chemicals and some complex catalyst

3. Hazard Identification

Non hazardeous ,may be harmful if inhaled .

General Advice: Wash off immediately with soap and plenty of water. In the case of respirable dust ,use self- contained breathing apparatus and dust impervious protective suit. Use personal protective equipment.

Skin Contact: Remove contaminated clothes and shoes, rinse skin with plenty of water or shower. Use soap to help assure removal.

Eye Contact: Remove any contact lenses at once. Flush eyes well with flooding amounts of running water for at least 15 minutes. Assure adequate flushing by separating the eyelids with sterile fingers. If irritation persists, consult a physician.

Ingestion: Rinse mouth, give plenty of water to dilute the substance. Never give anything by mouth to an unconscious person. Consult a phy

5. Handling and stotage

HANDLING: Avoid contact with eyes, skin and clothing. Avoid prolonged or repeated exposure. Handle material with suitable protection.

6.Storage:- Store away from sunlight in well- ventilated dry place at room temperature. Keep container tightly closed.

8. Physical and chemical properties Form :- Very fine, White coloured powder.

Solubility :- Soluble in water

pH value : 5.5 – 6.5 (10% Solution)

Nature : vegetable tannin extract.

Total Solids : 96 ± 1%

Stability and reactivity Thermal decomposition:- No thermal decomposition when stored and handled correctly.

Flammability:- Non flamable.

9 . Transport Information Proper Shipping Name: None

Non‐hazardous for transport: this substance is considered to be non‐hazardous for transport.

10. Disposal Consideration

Dispose in a hazardous- waste site in accordance with all applicable regulations.

11. Other information

No specific notes

The information above is believed to be accurate and represents the best information currently available to us. However, we make no warranty of merchantability or any other warranty, express or implied, with respect to such information, and we assume no liability resulting from its use. Users should make their own investigations to determine the suitability of the information for their particular purposes.

Formaldehyde scavenger for phenolic and Amino resin

POLYMATE -777-P& 777-A

Formaldehyde is a one of the most important starting materials in the chemical industry. It is used for example in the synthesis of urea formaldehyde resins, melamine resins, phenol formaldehyde resins,The issue of formaldehyde emission from composite wood products has been a concern, since the gas was deemed carcinogenic as per IARC. Europe has a set of standards for grading the plywood as per formaldehyde emission level, while India is yet to have any set of standards for plywood. Exporter prefers to to follow the European standardsIt is unclear how the limits of formaldehyde emissions for wood panels will change in different parts of the world in the future. The wood-based panel industry has so far reacted by applying appropriate formaldehyde scavengers (catchers). As a volatile organic compound (VOC), most of the formaldehyde is normally emitted from panels during production. There are two formaldehyde sources when producing wood panels: formaldehyde that might be contained in the adhesive and that in the wood material itself. The emissions can be reduced by either using formaldehyde scavengers.Formaldehyde scavenger is added directly to resin to reduce formaldehyde emission .Because of the aforementioned risks for human health there was a strong need for effective scavengers for formaldehyde.

Indian plywood Industries Research anf Training Institute (IPIRTI) taken our product as a project to study its efficacy and efficiency. IPIRTI certified the product with very good result. The report will be available if required.

Polymate -777-P (Scavenger for Phenolic Resin)

We are the first Indian Company to introduce scavenger by own manufacturing in wood based industry.

- It is used in Phenolic resin system and makes E1 and E0 emission label as per standers.

- It is basically addative produced by high label formaldehyde catcher like Lignin , Caprolactum and organic acid with some organic/inorganic amino additives.

- It is added during resin production to be fully active without any adverse effect in resin property.

- We ensure 100% for getting E0 result as per our guidence for uses.

- Cost effect is very less , Rs.0.6-0.7/sqft of glue line.

Appearance – Light browncolored fine powder

pH – 6.0 - 6.5 (1% solution )

Ionic Character – Non ionic

Activity -100%

Solubility _100%

Dosage – 0.5 - 1% as per requirement

Shelf life - More than 06 months

Identity:- Formaldehyde scavenger for wood adhesive,

1.CHEMICAL PRODUCT AND COMPANY

IDENTIFICATION PRODUCT NAME:- POLYMATE -777-P/A

MANUFACTURER:- PATINA CHEMICALS

2. Composition/information on ingredients

CHEMICAL NAME: - Formaldehyde scavenger is an additive composed by some speciality chemicals like Caprolactam, organic acid, Lignin with some inorganic and organic additives having amino as a functional terminating group .

3. Hazard Identification

Non hazardeous ,may be harmful if inhaled .

GENERAL ADVICE: Wash off immediately with soap and plenty of water. In the case of respirable dust ,use self- contained breathing apparatus and dust impervious protective suit. Use personal protective equipment.

Skin contact: Remove contaminated clothes and shoes, rinse skin with plenty of water or shower. Use soap to help assure removal.

Eye contact: Remove any contact lenses at once. Flush eyes well with flooding amounts of running water for at least 15 minutes. Assure adequate flushing by separating the eyelids with sterile fingers. If irritation persists, consult a physician.

Ingestion: Rinse mouth, give plenty of water to dilute the substance. Never give anything by mouth to an unconscious person. Consult a phy

5. Hanfling and storage

HANDLING: Avoid contact with eyes, skin and clothing. Avoid prolonged or repeated exposure. Handle material with suitable protection.

6.Storage:- Store away from sunlight in well- ventilated dry place at room temperature. Keep container tightly closed.

8. Physical and Chemical properties

Appearance – Light brown colored fine powder

pH – 6.0 - 6.5 (1% solution )

Ionic Character – Non ionic

Activity -100%

Solubility _100%

Dosage – 0.5 - 1% as per requirement

Shelf life - More than 06 months

9 . Transport Information

Proper Shipping Name: None

Non‐hazardous for transport: this substance is considered to be non‐hazardous for transport.

10. Diaposal Consideration

Dispose in a hazardous- waste site in accordance with all applicable regulations.

11. Other infornation

The information above is believed to be accurate and represents the best information currently available to us. However, we make no warranty of merchantability or any other warranty, express or implied, with respect to such information, and we assume no liability resulting from its use. Users should make their own investigations to determine the suitability of the information for their particular purposes.

Polymate -777-A (Scavenger for Amino Resin)

- It is used in amino resins like UF/MUF or MF resin and added during resin production.

- It is also our indigeneous product and introduced as only Indian Company to have for wood based industry.

- It is basically made of high label formaldehyde catcher like Caprolactum, organic acid and some inorganic amide with organic/inorganic amino additives.

- We ensure 100% for getting E1 and also E0 emission label standerd for amino resin product. result as per our guidence for uses.

- Cost factor also very insignificant in this system , Rs. 0.5-0.6 /Sqft of glueline.

Appearance – Light brown colored fine powder

pH – 6.0 - 6.5 (1% solution )

Ionic Character – Non ionic

Activity -100%

Solubility _100%

Dosage – 0.5 - 1% as per requirement

Shelf life - More than 06 months

Product description

Identity:- Formaldehyde scavenger for wood adhesive,

1.Chemical product and Company

Identification producct name:- POLYMATE -777-P/A

Manufacturer:- PATINA CHEMICALS

2. Composition/Infornation on ingredients

CHEMICAL NAME: - Formaldehyde scavenger is an additive composed by some speciality chemicals like Caprolactam, organic acid, Lignin with some inorganic and organic additives having amino as a functional terminating group .

3. Hazard Identification

Non hazardeous ,may be harmful if inhaled .

4. First Aid measires

General Advice: Wash off immediately with soap and plenty of water. In the case of respirable dust ,use self- contained breathing apparatus and dust impervious protective suit. Use personal protective equipment.

Skin contact: Remove contaminated clothes and shoes, rinse skin with plenty of water or shower. Use soap to help assure removal.

Eye contact: Remove any contact lenses at once. Flush eyes well with flooding amounts of running water for at least 15 minutes. Assure adequate flushing by separating the eyelids with sterile fingers. If irritation persists, consult a physician.

Ingestion: Rinse mouth, give plenty of water to dilute the substance. Never give anything by mouth to an unconscious person. Consult a phy

Handling: Avoid contact with eyes, skin and clothing. Avoid prolonged or repeated exposure. Handle material with suitable protection.

6.Storage:- Store away from sunlight in well- ventilated dry place at room temperature. Keep container tightly closed.

8. Physical and chemical properties

Appearance – Light brown colored fine powder

pH – 6.0 - 6.5 (1% solution )

Ionic Character – Non ionic

Activity -100%

Solubility _100%

Dosage – 0.5 - 1% as per requirement

Shelf life - More than 06 months

9 . Transport Information Proper Shipping Name: None

Non‐hazardous for transport: this substance is considered to be non‐hazardous for transport.

10. Disposal Consideration

Dispose in a hazardous- waste site in accordance with all applicable regulations.

11. Other information

The information above is believed to be accurate and represents the best information currently available to us. However, we make no warranty of merchantability or any other warranty, express or implied, with respect to such information, and we assume no liability resulting from its use. Users should make their own investigations to determine the suitability of the information for their particular purposes.

Fire Retardant Chemicals

FRM-111

(Impreganating Chemical)

- It is mixture of Phosphorus, Nitrogen and Boron based additives.

- Light grey powder

- Core veneer , wooden strips are dipped in its solution (4-5% solution) for 40-45 mins at tempatature of 60-70 degree centigrade.

- Nitrogen, Boron and phosphorus goes in to pores of core at wooden planks and creates synergetic effect for fire retardancy.

- Cost effect is well in limit.

FRM-222

(Fire Retardant Additive)

- It is mixture of otganic phosphorus , Nitrogen Compounds

- Light grey powder

- It is used in glue by mixing 2-3% with resin , both phenolic and amino resin system.

- It reaches in every pores of wood with glue during hot pressing and makes plywood and doors more fire retardant in nature.

- So this marterial is very effective in its uses but with very less cost impact(hardly 1%)

FRM-333

(Fire Retardant Coating)

- Basically polyphosphate based compound.

- It is used by mixing (2-3%) with preservative solution (ACC/CCD)

- Plyboards are dipped in this solutions makes non-hygroscopic in nature. So lamination wood not be any problem on ply or doors.

- Cost factor is also less (<2%)

FRM-444

(Ceramic Fiber sheet)

Ceramic Fiber sheet is processed from the high purity fiber, which can be used in the field of high temperature insulation. It is Low Thermal Conductivity .Excellent Thermal Electrical Insulation, can be used as for manufacture of fire resistant door as per IS 3614 & 476

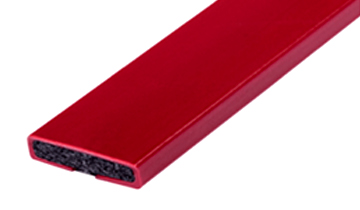

FRM-555

It is aIntumescent seal for fire rated timber door to be fitted at edges and frames

Application: Fire resisting timber door set

Fire Resistance Period: 30 to 120 minutes

Insulation/integrity: Integrity and insulation

Laminating Adhesive

LPA-111

Water based coldsetting adhesive for laminate pasting on plywood,Blockboard ,flushdoor at lowercost,strong bonding and better water resistance property (i.e upto 3/4 hrs water resistance of laminates @1000C.)

LPA-222

Water based coldsetting adhesive for FURNITURE WORK ,FINGERJOINING ETC at lowercost,strong bonding and better water resistance property (i.e upto 3/4 hrs water resistance of laminates @1000C.)